Driven:

PCB Control

Filtration:

Single layer strainer

Cleaning:

Power Suction Head

Control:

Differential pressure & timer

Filtration Rating:

10 ~ 3000 micron

Washing Time:

10 ~ 60 seconds

Pressure Lost:

Less than 0.018MPa

Max. Temperature:

95 degree C

Max. Pressure:

1.0 MPa

Housing Material:

Carbon steel with inner epoxy coating, SS 304, SS 316L, SS 2205

Filter Screen Material:

SS 304, SS 316L, SS 2205

Seal Material:

Viton

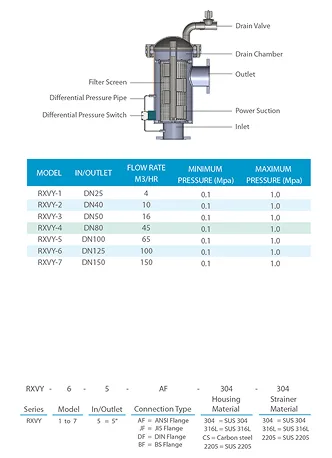

Filtration Process

Water flows in from the inlet, fully fill in the internal of the filter screen and drain chamber while the drain valve is closed. Water starts going through the filter screen from internal to external. Filtered water will flow out from the outlet. During the Filtration Process, inlet pressure (bottom) become higher and higher while outlet pressure (top) become lower and lower. When differential pressure between inlet and outlet has built up to 2 bar or the timer has achieved the setting time, the Cleaning Process will be started.

Cleaning Process

When the drain valves opens, foreign particles inside the filter screen and drain chamber will be flushed out through the drain valve. The liquid flow will crease a suction force at the power suction nozzles which will suck the foreign particles in the internal part of the fine filter screen. During the cleaning process, the foreign particles sticking on the internal part of the fine filter screen will be flushed out through the drain valve.

Filtration Process Again

After 30 to 60 seconds of the cleaning process, the drain valve will close and the filtration process will resume its operation

Reviews

There are no reviews yet.